2019-01-17T11:19:32

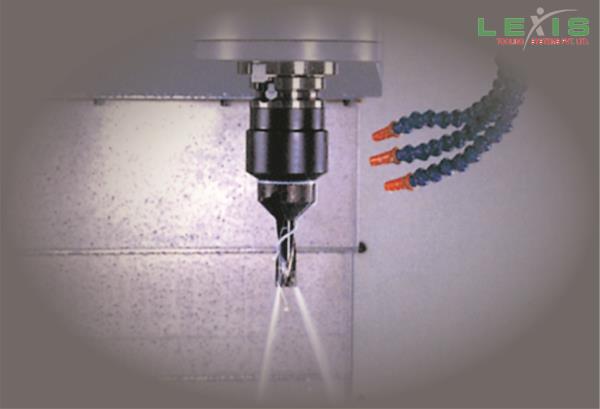

Spindle Thro Coolant Collets The manufacturing industry trusts significantly on CNC (Computer Numerical Control) machining process, because it provides efficient, expedient and precise production capacity ideal for creating large quantities of items normally produced with a Turning Center, vertical Milling machine, Router, Grinding machine, Center lathe. Lexis tooling systems identified as premier company in manufacturing machine tool accessories, Lexis toolings aware that the highest-quality products start with the very best toolings, hence we are secure to manufacture and ensuring high quality tooling products to our customers. For the Machine Tool Industry Lexis Tooling committed to offer high precision tooling to worldwide via its distributor network thro its wide range of products which includes ER Collets, TG Collets, DA Collets, NC Collets, Coolant Collets, Sealed Collets, Tapping collets, ORT Collets, Collet Chucks, Straight Collets used in High power Milling chuck, Hydro Grip Reduction Sleeves, Tool Holders, Pullstuds and Clamping Nuts. All our regular thro coolant collets withstands 70 bar (ie 1000 psi) application pressures. The main advantages of Spindle thro coolants Collets on drilling, hole quality, throughput, tool speed and life. Again CNC machining industry continues to innovate and improve according to the customer requirement. As a part of contribution to Machining industry Lexis tooling has improved performance of Coolant collets which can withstand 2000psi (140 bar) for special application integrating through-spindle coolants into your machines and reap the benefits in quality, delivery, and overall productivity. In Lexis tooling we have variant thro coolant solutions available in our manufacturing range. ER Sealed Collet (Internal thro coolant) & ER Sealed Collet (External thro coolant), DA Coolant Collet, TG Coolant Collet & ER Tap Sealed Collets, RDO Coolant Collet & RDF Coolant collet, Flange thro coolant Tool Holders, Hydro Grip Sleeves thro coolant type etc. Our Moto is to offer, customized tooling solutions to increase the efficiency of our customer machining operations

Have a question? Ask here!

Required fields are marked *